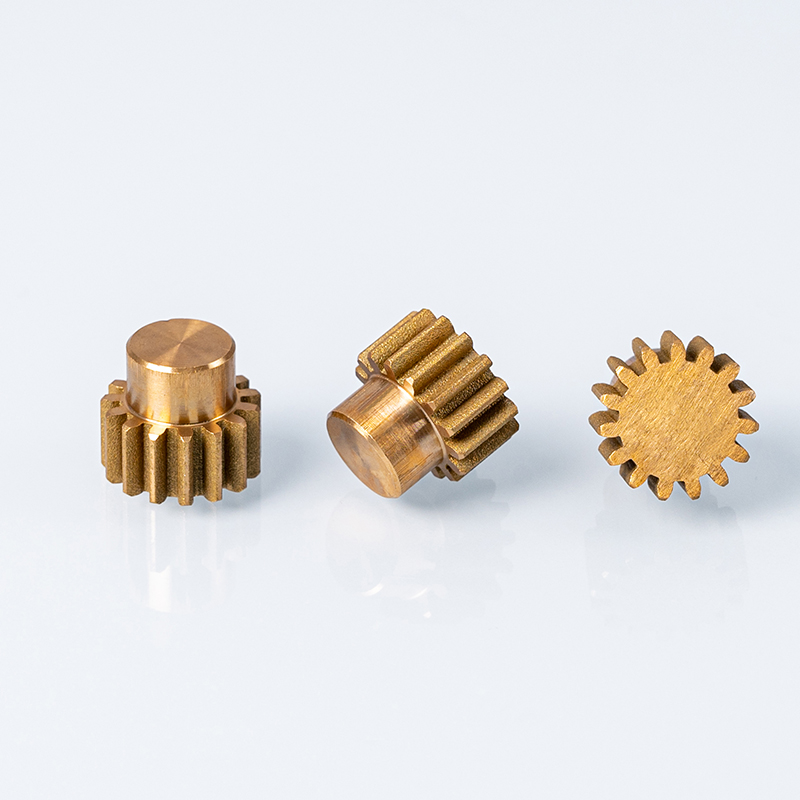

Yakakwira chaiyo cnc machining mumhangura

Kufunga kweCnc machining zvikamu ne copper

CNC machining yemari inotaura nezve maitiro emachining machipper zvikamu zvichishandisa komputa nhamba yekudzora (CNC) michina. Kuita uku kunosanganisira kushandiswa kwekucheka maturusi, senge madhiraivha uye kuguma mamirimita, kuumba mhangura mune yakadiwa chimiro uye saizi. Maitiro eCNC machinini akanyatsokodzera, achibvumira kuti gadziriswe zvigadzikiso kugadzirwa nehuremu hwakanyanya hwekujeka.

Iyo yakajairika mhando yemhangura inoshandiswa kune cnc machining ndeye c110. Rudzi urwu rwemhangura rwakakodzera ku cnc machining nekuda kwekushomeka kwayo kwakanyanya uye simba. Mamwe madhiri emhangura, akadai saC145 naC145, anogona kushandiswa kuchina che cnc zvichienderana neshandare.

Zvishandiso zvekucheka zvinoshandiswa kune cnc machining mhangura inofanirwa kuve yakagadzirwa neyekumhanya-kumhanya simbi kana barbide. Izvi zvigadzirwa zvinokwanisa kutsungirira kupisa kwakanyanya kwakagadzirwa panguva yemachina maitiro. Pamusoro pezvo, maturusi ekucheka anofanirwa kuve akapinza uye akakodzera akanyatsojekesa kuti ave nemachina anonyatso.

Iyo CNC machining maitiro zvakare inodawo kushandiswa kwekutonhora kubatsirwa kubvisa machipisi uye zvidimbu kubva pabasa rekushanda. Pamusoro pezvo, iyo inotonhorera inobatsira kuderedza kupisa kuvaka-kumusoro uye kuwedzera hupenyu hwechishandiso chekucheka.

Mukana weCNC machining mhangura

CNC machinning mhirizhonga yemusoro inopa zvakawanda zvakanakira, zvakadai sekunyatsojeka uye kunyatsoita, kusimbisa kwehuremu, kwakawedzera kudzikisira kwesimbi

1. Simba repamusoro uye kusimba - mhangura ndiyo zvinhu zvakanyanyisa zvinowanikwa uye zvinokwanisa kutsungirira kupisa kwakanyanya, kumanikidzwa nekupfeka. Izvi zvinoita kuti ive sarudzo yakanaka yekunyora kwemachina, sezvo inogona kushandiswa mune dzakasiyana siyana dzekushandisa uye dzinokwanisa kutsungirira iyo genige yekudzokorora, yakakwirira-chaiyo mashandiro emuchina.

2.. Izvi zvinovimbisa kuti chigadzirwa chakapedza chichava neyekutanga chikamu chekujeka uye chaicho.

3

4

5. Zviri nyore kushanda ne - mhangura ndeyekunyora zvinhu zviri nyore kushanda naye, kubvumira kukurumidza kugadzirwa uye kurongeka kukuru.

Yakatora sei muCNC machining michina

CNC machining michecha yendima dzinosanganisira kushandiswa kwekunyora zvidimbu zvekucheka maturusi akadai sekupedzisira makomo kuti ubvise zvinhu kubva pane zvekushandisa zvinoenderana nenzira yakarongerwa. Iyo purogiramu yeCNC machino inoitwa kuburikidza nekombuta-inobatsira dhizaini (CAD) software uye inobva yatenderwa kumuchina kuburikidza ne g code, inobvumidza kuitisa kufamba kwega kwega. Zvikamu zvemhangura zvinogona kubhinywa, zvakanyorwa kana kutenderwa zvichienderana nekunyorwa. Metalwork's svutugadzike inowanzoitwa panguva ye cnc machining maitiro, kunyanya kana uchibata nesimbi dzakaoma kunge mhangura dzinoda imwe lubrication.

CNC machining macheya emhangura ndiyo machinji maitiro ekushandisa kombiyuta nhamba dzinotongwa Copper inoshandiswa mune dzakasiyana siyana dzeCNC zvinyorwa zvinosanganisira kuratidzira, kuumbwa, zviumbwa, uye zvikamu zvekupedza.

CNC machinning mhirizhonga inoda kushandiswa kweanoshandiswa software uye cnc michina iyo yakashongedzerwa zvishandiso zvakakodzera kutemwa uye kuumba zvinyorwa. Maitiro acho anotanga nekugadzira iyo 3D muenzaniso weiyo inodiwa chikamu muchirongwa che cad. Iyo 3D modhi inoshandurwa kuita nzira yekushandisa, iyo iri seti yemirairo iyo chirongwa cheCnc muchina kuburitsa chimiro chaunoda.

Iyo CNC muchina unobva waremerwa neyakakodzera yekushandisa, yakadai sekupedzisira milli uye yekudhirowa mabheti, uye zvinyorwa zvinobva zvaremerwa muchina. Izvo zvinyorwa zvinobva zvasvika zvinoenderana nenzira yakarongerwa nzira uye chimiro chaunoda chinogadzirwa. Mushure mekunge maitiro emachina apera, chikamu chinoongororwa kuti chive nechokwadi chekuti zvinosangana zvakatemwa. Kana zvichidikanwa, chikamu chacho chinobva chapera nemhando dzakasiyana-siyana dzepost-machines dzakadai sekubika uye kupukuta.

Ndezvipi zvikamu zveCNC machinji zvinogona kushandisa mhodzi

CNC machining mari yemhangura inogona kushandiswa kune akasiyana-siyana ekushandisa, kusanganisira zvikamu zvemagetsi uye zvinobatanidza, zvakakwirira-zvemagetsi emagetsi, zvinhu zvekushandisa, zvishandiso zvekurapa, zvigadzirwa zvekurapa, midziyo yakaoma. Copper cnc know zvikamu zvinowanzoiswa nedzimwe simbi dzekuvandudza kufambidzana kana kupfeka kuramba.

CNC machining mari yemhangura inogona kushandiswa zvakasiyana-siyana zvekushandisa, kusanganisira zvinobatanidza zvemagetsi, nyanzvi dzekutsinhana, kupisa simba, zvikamu zvimiro, uye zvigadzirwa zvekushongedza. Zvikamu zvemhangura zvakanakira cnc machining nekuda kwemakona ayo epamusoro nemagetsi, uye zvakanakisa kurwisa kupesana. CNC machinisheni yemachinda inogona zvakare kushandiswa kugadzira maumbirwo akajeka uye zvikamu zvine zvirevo chaizvo.

Rudzii rwekurapa kwemusoro rwakakodzera kune cnc machining zvikamu zvemhangura

Iyo yakakodzera kwazvo pamusoro pekurapa kweCnc machining yemhangura zvikamu zveCopper zvikamu zvinozivikanwa. Anodizing chiitiko chinosanganisira Electro Kumirira kurapa simbi uye kugadzira nzombe yehusiku pamusoro pezvinyorwa zvinowedzera kupfeka kupfeka uye dziviriro yekora. Inogona zvakare kushandiswa kupa kushongedza kupedzisa semavara anopenya, matte apedza kana kupenya matanho.

Alloys the they inowanzo kubatwa neyemagetsi nickel plething, anodizing, uye kupatsanura kuchengetedza pasi kubva pakubata uye kupfeka. Maitiro aya anoshandiswawo kugadzirisa aesthetics echikamu.

Chikumbiro:

3C indasitiri, mheni yekushambadzira, magetsi emidziyo, auto emidziyo, zvigadzirwa zvemidziyo, zvishandiso zvemagetsi, zvishandiso zvezvekurapa, zvimwe zvekutakura zvinhu zvekutakura.