Kune akati wandei epamusoro marapirwo anogona kushandiswa kune CNC machined aluminium zvikamu.Mhando yekurapa inoshandiswa ichaenderana nezvinodiwa zvechikamu uye kupera kunodiwa.Heano mamwe akajairika epamusoro kurapwa kweCNC machined aluminium zvikamu:

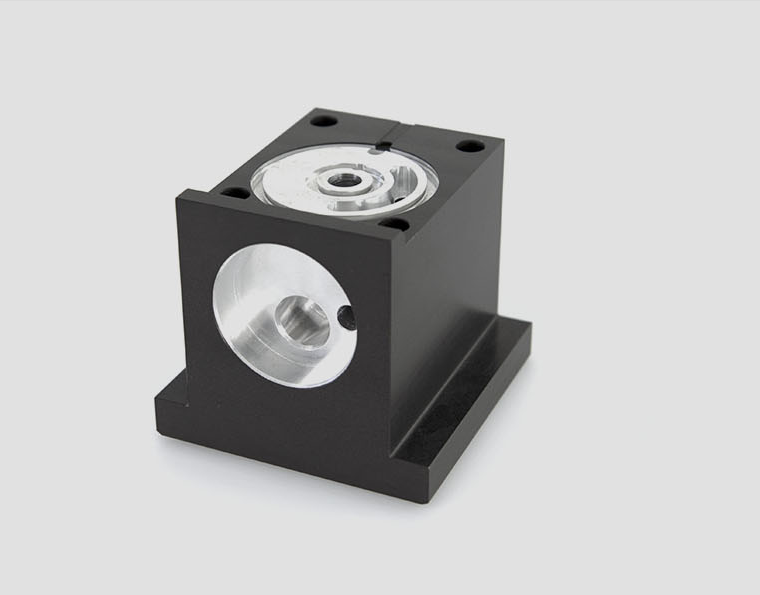

1. Anodizing / Hard anodized

Iyi inzira iyo oxide layer inokura pamusoro pealuminium.Anodizing inogona kupa kupera kwakasimba, kusaita ngura inogona kudhayiwa kune akasiyana mavara.Inogona kuve yakajeka, dema, tsvuku, bhuruu, yepepuru, yero kana chero mavara aunoda zvichienderana nedhizaini yako.

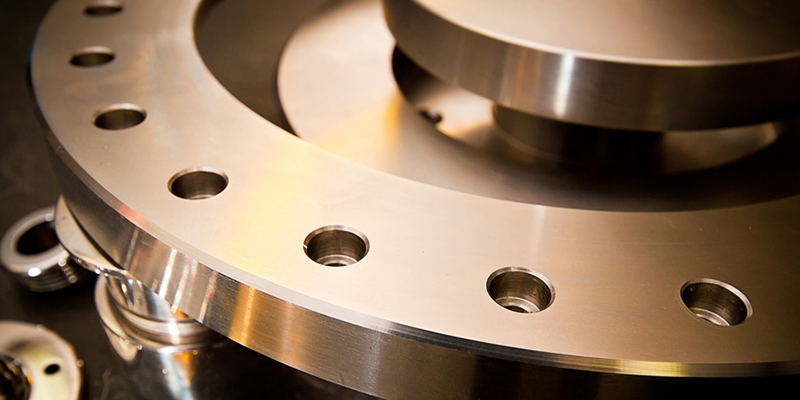

2. ALTEF (Teflon)

ALTEF(Teflon) imhando yekurapwa kwepamusoro inoshandiswa muCNC machini zvikamu.Inomirira Aluminium Teflon Electroless Nickel Plating, uye inosanganisira kuisa chidimbu che electroless nickel pamusoro pechikamu chealuminium, chichiteverwa nechikamu cheTeflon.

Iyo ALTEF maitiro anoshandiswa kuvandudza kupfeka kuramba uye kuderedza friction coefficient yealuminium zvikamu.Electroless nickel layer inopa yakaoma, inodzivirira corrosion iyo inovandudza kusimba kwechikamu, nepo Teflon layer ichideredza coefficient yekukweshana pakati pechikamu nedzimwe nzvimbo, ichivandudza kutsvedza kwechikamu.

Iyo ALTEF maitiro inoshanda nekutanga kuchenesa chikamu chealuminium kubvisa chero tsvina kana tsvina.Chikamu chinobva chanyudzwa mumushonga une electroless nickel plating chemicals, iyo inoisa chidimbu chenickel pamusoro pechikamu kuburikidza ne autocatalytic process.Iyo nickel layer inowanzotenderedza 10-20 microns gobvu.

Zvadaro, chikamu chacho chinoputirwa mumushonga une Teflon particles, iyo inonamatira kune nickel layer uye inoumba mutete, yunifomu yeTeflon pamusoro pechikamu.Iyo Teflon layer inowanzotenderedza 2-4 microns gobvu.

Mhedzisiro yemaitiro eALTEF ndeyekupfeka-kusagadzikana uye yakaderera-kukweshana pamusoro pearuminiyamu chikamu, iyo yakanakira kushandiswa mune yepamusoro-inoshanda uye nemazvo maapplication, akadai seaerospace, mota, uye maindasitiri ekurapa.

3. Powder Coating

Iyi inzira iyo poda yakaoma inoiswa nemagetsi pamusoro pealuminium uye yobva yabikwa kuti iite yakasimba, yekushongedza kupera.

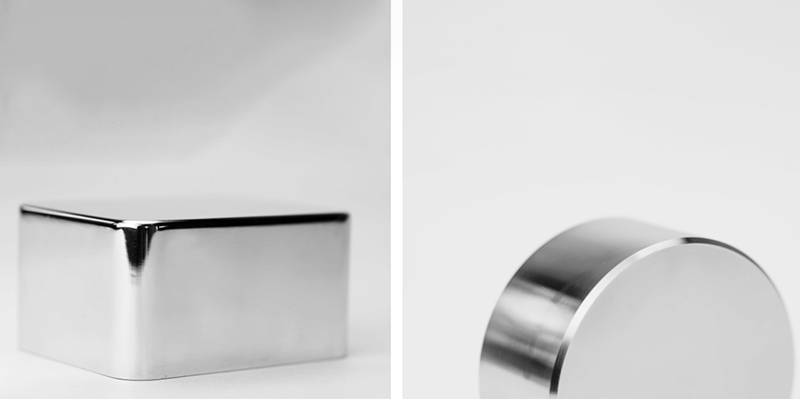

4. Kemikari Polishing

Iyi nzira inoshandisa makemikari kubvisa zvishoma zvinhu kubva pamusoro pealuminium kuti igadzire kupera, kupenya.

5. Mechanical polishing

Kuita uku kunosanganisira kushandisa nhevedzano yemabrasives kubvisa zvinhu kubva pamusoro pealuminium kugadzira kutsetseka, kupenya kupera.

6. Kuputika kwejecha

Kuita uku kunosanganisira kushandisa mhepo inodzvanyirira kana mvura kupusha jecha kana zvimwe zvinhu zvinokuvadza pamusoro pealuminium kugadzira kupera kwemavara.