CNC machining muStainless simbi

Zvinhu zviripo:

Simbi isina tsvina 304/304L| 1.4301/1.4307| X5CrNi18-10:Stainless simbi 304 ndiyo yakajairika simbi isina tsvina. Iyo chaiyo isiri-magineti simbi uye ishoma magetsi uye thermally conductive pane kabhoni simbi. Inoshandiswa zvisingaite nekuti inoumbwa nyore mumhando dzakasiyana siyana. Iyo inogoneka uye inokwenenzverwa. Mamwe mazita esimbi iyi ndeaya: A2 Stainless steel, 18/8 Stainless steel, UNS S30400, 1.4301. 304L simbi isina tsvina ndiyo yakaderera kabhoni vhezheni yesimbi isina tsvina 304.

Stainless simbi 316/316L | 1.4401/1.4404 | X2CrNiMo17-12-2:Yechipiri inoshandiswa zvakanyanya simbi isina simbi mushure me304, iyo general chinangwa austenitic Stainless simbi 316 ine yepamusoro corrosion resistance kunyanya muchloride ine nharaunda uye yakanaka yakakwira tembiricha simba. Iyo yakaderera kabhoni vhezheni 316L ine zvirinani kuomarara kuramba mune welded zvimiro.

Stainless simbi 303 | 1.4305 | X8CrNiS18-9:Giredhi 303 ndiro rinonyanya kugadzirwa mushini pane ese austenitic mamakisi esimbi isina tsvina. Icho chiri kunyanya kugadzirisa machining os simbi isina tsvina 304. Ichi chivakwa chinokonzerwa nepamusoro pesarufa kuvapo mumakemikari. Kuvepo kwesarufa kunonatsiridza machinability asi zvishoma kudzikisa kusimba kwekuora uye kuomarara kuchienzaniswa neiyo yesimbi isina tsvina 304.

Tsanangudzo yesimbi isina tsvina

Stainless simbi imhando yesimbi alloy yakagadzirwa kubva musanganiswa wesimbi uye inokwana 10.5% chromium. Iyo inoshingirira zvakanyanya mukuora, ichiita kuti ive yakakodzera kune dzakasiyana siyana dzekushandisa, kusanganisira yekurapa, otomatiki maindasitiri uye basa rekudya. Iyo chromium yemukati musimbi isina tsvina inoipa akati wandei akasiyana zvivakwa, zvinosanganisira epamusoro simba uye ductility, yakanakisa kupisa kupisa uye isiri-magineti zvivakwa. Simbi isina tsvina inowanikwa mumhando dzakasiyana-siyana dzemagiredhi, imwe neimwe iine zvivakwa zvakasiyana kuti ienderane nemashandisirwo akasiyana. SeCNC machining muchina shopu muChina. Ichi chinhu chinoshandiswa zvakanyanya mumichina chikamu.

Kubatsira kwesimbi isina tsvina

1. Durability - Stainless simbi chinhu chakanyanya kuoma uye chakasimba, chinoita kuti chisamirire kune dents uye zvikweshwa.

2. Corrosion Resistance - Simbi isina simbi inoshingirira mukuora, zvichireva kuti haiite ngura kana kuita ngura kana yasangana nehunyoro kana mamwe maasidhi.

3. Low Maintenance - Simbi isina tsvina iri nyore kwazvo kuchenesa nekuchengetedza. Inogona kupukutwa pasi nejira nyoro uye haidi chero yakakosha yekuchenesa mhinduro kana polishes.

4. Mutengo - Simbi isina simbi inowanzoita mari yakawanda kupfuura zvimwe zvinhu zvakaita semarble kana granite.

5.Versatility - Simbi isina tsvina inogona kushandiswa kune zvakasiyana-siyana zvekushandisa, mukati uye kunze. Inowanikwawo mumhando dzakasiyana dzekupedzisa uye masitayera, zvichiita kuti ive sarudzo yakanaka kune chero imba."

High tensile simba, ngura uye tembiricha inodzivirira. Stainless simbi alloys ane yakakwirira simba, ductility, kupfeka uye ngura kuramba. Iwo anogona kuve akakwenenzverwa, akagadzirwa uye akakwenenzverwa mu cnc muchina masevhisi.

| Simbi isina tsvina 304/304L | 1.4301 | X5CrNi18-10 |

| Simbi isina tsvina 303 | 1.4305 | X8CrNiS18-9 |

| Simbi isina tsvina 440C | 1.4125 | X105CrMo17 |

Sei Stainless simbi muCNC machining zvikamu

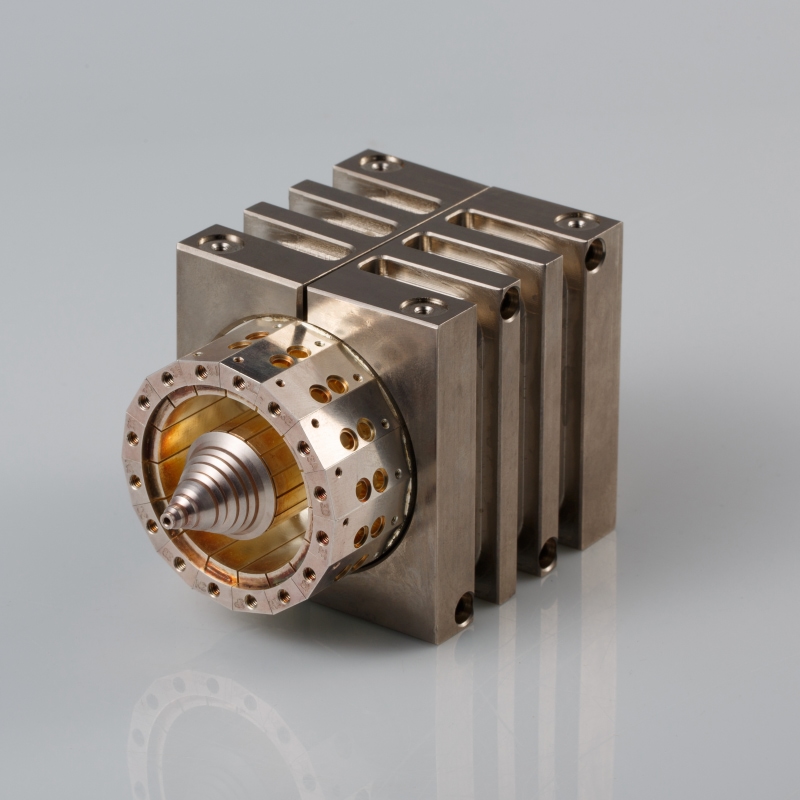

Simbi isina simbi isarudzo yakakurumbira yeCNC machining zvikamu nekuda kwekusimba kwayo, simba, uye kusagadzikana kwekuora. Inogona kugadzirwa kune yakasimba kushivirira uye inowanikwa mumhando dzakasiyana siyana uye kupera. Simbi isina tsvina inoshandiswa mumaindasitiri akasiyana-siyana, seyekukurumidza prototype kubva kukurapa kuenda kune aerospace, uye yakanakira maapplication anoda kusimba kwepamusoro uye kusagadzikana kwekuora."

Izvo CNC machining zvikamu zvinogona kushandisa kune Stainless simbi zvinhu

Iwo akajairika CNC machining zvikamu zveStainless simbi zvinhu zvinosanganisira:

1. Magiya

2. Shafts

3. Makwenzi

4. Mabhaudhi

5. Nzungu

6. Mawachi

7. Spacers

8. Standoffs

9. Dzimba

10. Mabhureki

11. Fasteners

12. Heat Sinks

13. Kukiya zvindori

14. Zvisungo

15. Zvibatanidza

16. Plugs

17. Adapter

18. Mavharuvhu

19. Fittings

20. Zvakawanda"

Ndeupi rudzi rwekurapwa kwepamusoro kwakakodzera CNC machining zvikamu zvesimbi isina tsvina

Iyo inonyanya kuzivikanwa pamusoro pekurapa kweCNC machining zvikamu zvesimbi isina tsvina ndeyejecha, passivation, electroplating,Black oxide, Zinc plating,Nickle plating,Chrome plating,Powder coating,QPQ nekupenda. Zvichienderana nemashandisirwo chaiwo, mamwe marapirwo akadai semakemikari etching, laser engraving, bead blasting uye polishing anogona zvakare kushandiswa.